Copyright © 2021 Danas, All rights reserved.

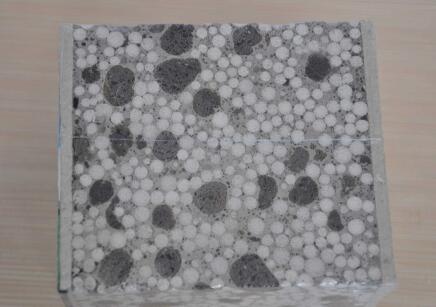

EPS Cement Sandwich Wall Panel

EPS cement sandwich panel without face board

Eps ceramicite sandwich wall panel

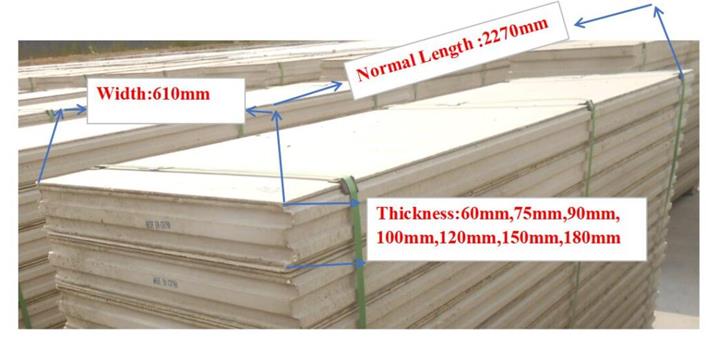

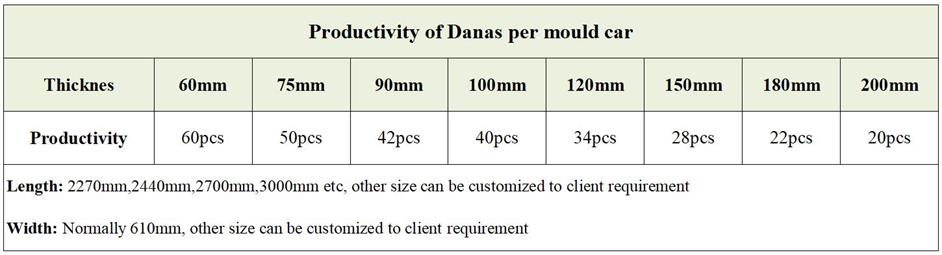

Length: 2270mm/2440mm/2700mm/3000mm, other size can be customized

Width: 610mm/600mm,other size can be customized

Thickness: 60mm/75mm/90mm/100mm

/120mm/150m/180mm/200mm,

other size can be customized

For low/multi-story/high buildings

Such as: Condominium(apartment), hotel, office building, school, commercial building, hospital, shopping mall etc

Such as: School, shopping mall, resort, villa, economical house etc

Remarks: If you use Danas panel as fence wall, suggest support with steel structure & specific details etc check with Danas team first

Remarks: If use wall panels as roof &floor, need to support by steel structure.

3 types machines:

(1) Manual machines

(2)Semi-automatic machines

(3) Fully automatic machines

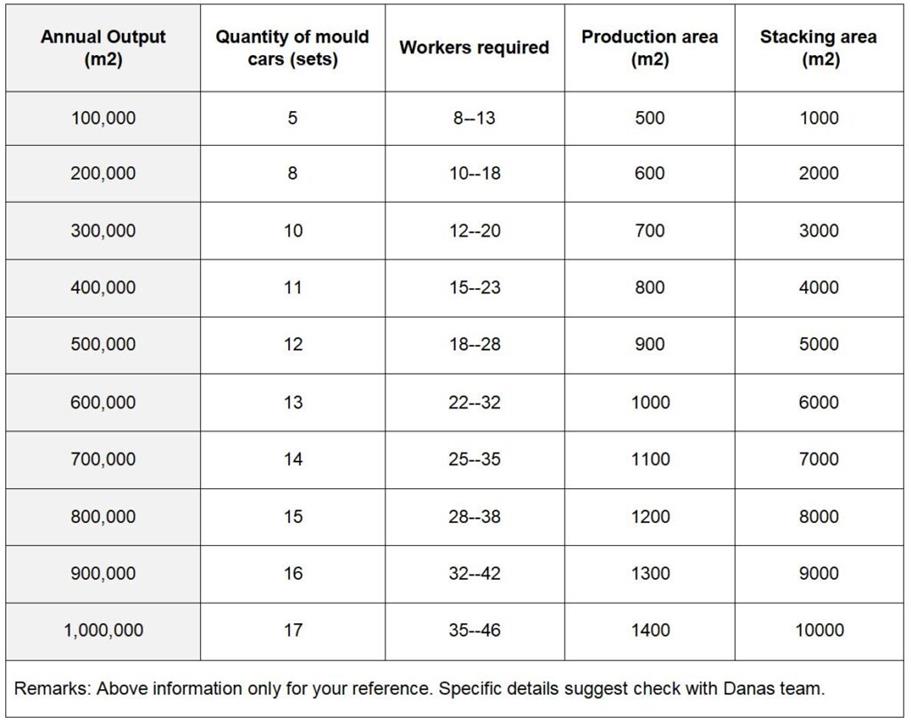

Annual productivity

range from 100,000m2 to 1,000,000m2

Different annual productivity with diffeerent quantity of mould cars, production area, stacking area etc.

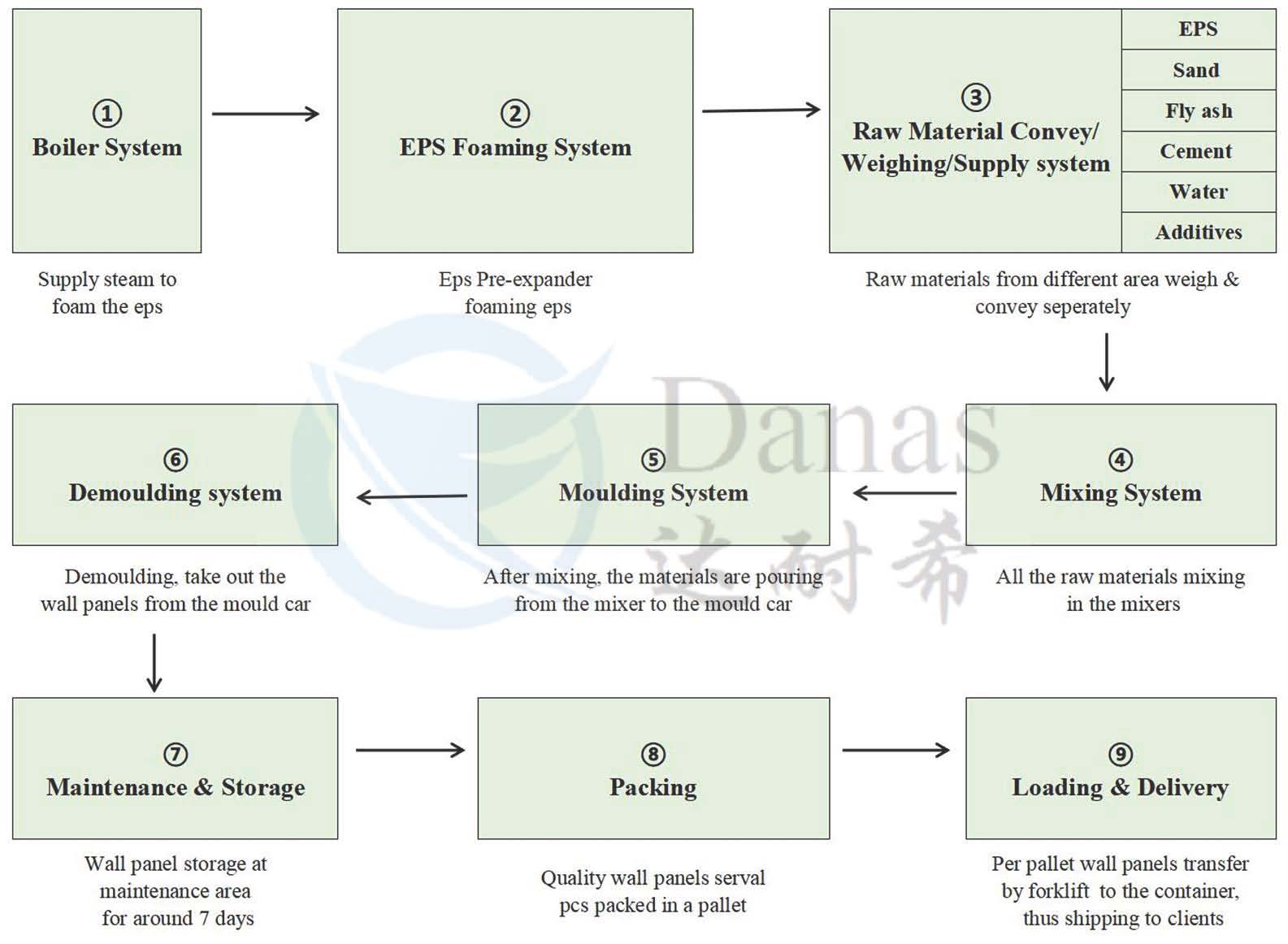

(1) Boiler System

(2) Foaming system

(3) Raw Material Convey/Weighing/Supply system

Cement silo & screw conveyor

Cement silo

(4) Mixing system

According to different annual productivity, can offer JS1000, JS1500, JS2000 mixing machine, also can offer 1 set or 2 sets of JS1000, JS1500 etc

(5) Moulding system

(6) Demoulding system

7. Productivity & different types of Danas mould car

Different types of mould car:

Option 1: Mould car producing panels without face board

Remarks: If produce panels without face board, wall panel length should be shorter than normal panels, suggest wall panel length around 1.2-1.8m or easy to broken.

Option 2: Most commonly used mould car

Option 3: Pulley mould car

Option 4: High advanced mould car

(1) Over 20 years life time of the machines

(2) Qualtiy guarantee : 1 year

(3) After sales support: whole life time of machines

(4) Engineers guide installation & debug of the machines at factory

(5)Engineers traning your workers to produce the quality wall panels

(6) Automatic production system, with high output & less workers

(1) Investment cost calculation

(2) Factory area design

(3) Production line layout design

(4) Production capacity calculation

(5) 24 hours online after sales service

1.Raw materials: EPS, sand, cement, calcium silicon board, water, addictives and ect. (your local materials can also be used)

2.Land, factory, foundation etc

3.Water 4. Electrical

5. Auxiliary installation machines & workers

Remarks: Face board also can use fiber cement board or mgo board according to client requriement)

Email: sales@danasbuildingmaterial.com

Mobile/Whatsapp: +86-13317179258

Wechat: Danaswall

After note more details of our line, if you do intersted our wall panels & want a sample to check the quality

Can send by DHL, Fedex, UPS etc

Danas production line quotation —-your target price —bargain —bargain —finally agree by two sides

Such as payment terms, delivery time, quality assurance, shipping plan etc

All details confirmed, place an order, then we send you Proforma Invoice, you pay 30% deposit payment

Upon receive 30% deposit, will arrange production & will update the production process regularly

When goods finished production, we will show you the picture (video), you can arrange your QC to check the quality, then to arrange the balance payment

Contact with the forwarder, booking container for loading the wall panels

Loading the wall panels into container, take photos or videos thus to send client for reference

Send draft B/L, Packing list, Commercial invoice, CO etc for confirmation, then to send original sets or telex documents

Always track the container sailing details & remind client 7 days before container arrive to destination port , thus client can make customs clearance & pick up for containers etc in advance

After pick up the container, unloading the goods, suggest check the quality within 10 days If happen to any broken pcs, please do not worry, we always here for your after service service

Remarks: This is the normal procedure, only for your basic reference. No need to follow all this step one by one, different client with different practice , welcome to contact for further details .

More details needed, feel free to contact with us

Website: www.danasbuildingmaterial.com Email: sales@danasbuildingmaterial.com

Mobile/Whatsapp: +86-13317179258 Wechat: Danaswall

Thank you so much for your kindly patience of our eps cement sandwich wall panel page, hope to cooperate with you in future.