Danas Eps Cement Sandwich Panel Product Page

1. Introduction of Danas eps cement sandwich panel

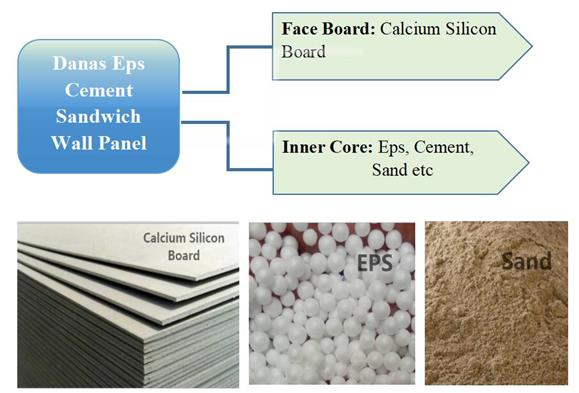

What is eps cement sandwich panel?

Danas eps cement sandwich panel, we also named eps wall panels, eps sandwich wall panels,eps cement wall panel, eps cement sandwich wall panels, eps cement board sandwich panel, lightweight eps concrete wall panel etc.

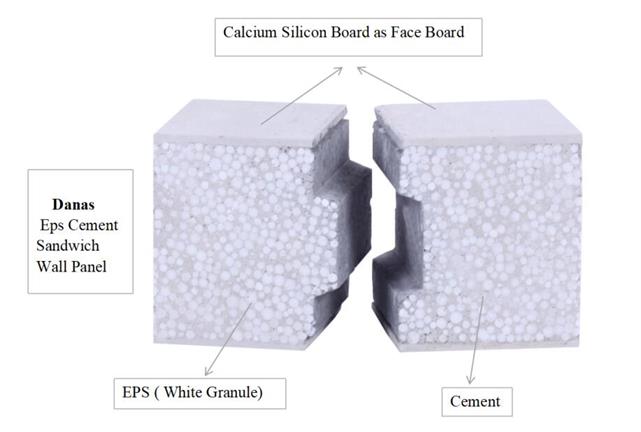

It is a kind of lightweight compound sandwich wall panel, using calcium silicon board (or fiber cement board) as the face board, eps, sand, cement etc as the inner core, to be compound at one time.

Raw material of Danas eps cement sandwich panel

Face Board: Calcium silicon board

Inner core: EPS, Cement, Sand etc mixing together

Remarks: Face board also can use fiber cement board or mgo board according to client requriement)

2. Application of Danas eps cement wall panel

Danas eps cement wall panel mainly use for internal & external wall, also use for fence wall, roof & floor etc

Internal wall

For low/multi-story/high buildings

Such as: Condominium(apartment), hotel, office building, school, commercial building, hospital, shopping mall etc

External wall

For less than 6 floor building

Such as: School, shopping mall, resort, villa, economical house etc

Fence Wall

Remarks: If you use Danas panel as fence wall, suggest support with steel structure & specific details etc check with Danas team first

Roof

Floor

Remarks: If you want use Danas eps cement sandwich wall panel as the roof &floor, need to support with steel structure

Specific details suggest check with Danas team.

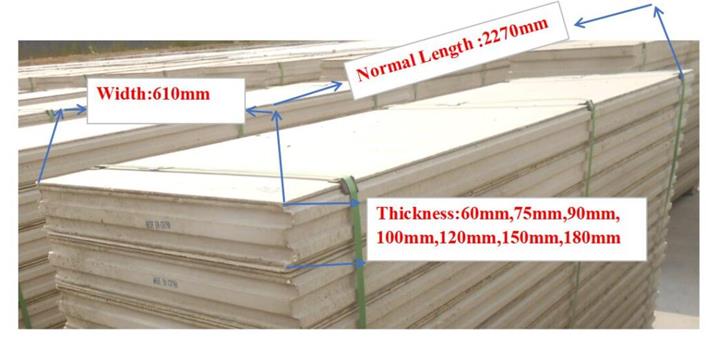

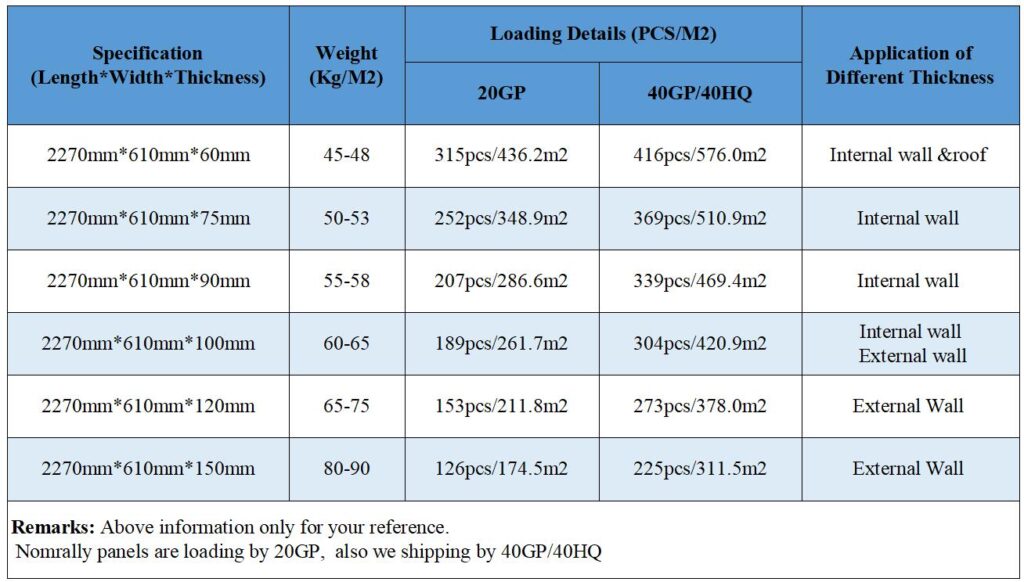

3. Specification & loading details

Specification

Normal length is 2270mm, 2440mm, 2700mm etc can be customized

Remarks: Cutomizing details etc further discuss by email

Loading &

Application

Remarks: Specific details suggest check with Danas team.

4. Features of Danas Eps Cement Panel

- Light weight—1/6 of traditional brick, one worker can carry easily

- Eco-friendly —100% not asbestos

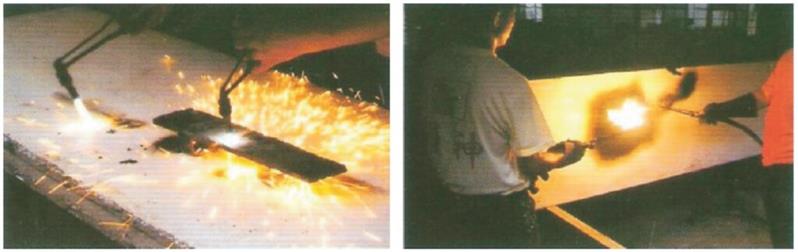

- Fire-proof— 2 to 4 hours (Tested on 1000 degree, panels without damage; base on GB/T9987)

- Sound Insulation—- 38dB for 60mm, 46dB for 150mm

- Waterproof and damp proof—–Below picture for your reference

- Heat Insulation and preservation— 5 ℃differences between indoor& outdoor

- Best hanging force—single point hanging strength: 50kg

- Anti-seismic and impact resistance— anti-earthquake class 7

- Area-saving— save 4 m² / 100 m² (compare with traditional building materials)

- Fastconstruction: 3 experienced workers in a group, can install 90m2/day

Fireproof

Best Hanging Force

Waterproof

Lightweight

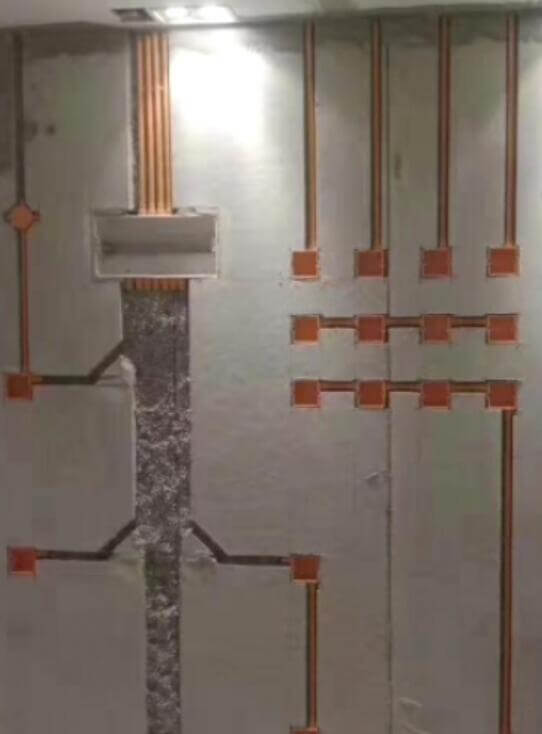

Waterpipes & electric wire

5. Engineering Cases

(1) High Building Partition Wall

Condomium

Office Building

Apartment

Mixed Used( Hotel & office Building)

Hospital Internal Partition Wall

(2) Multistory building internal & external wall

Teaching building

Student domitory

Shopping mall

Apartment (Internal & external wall)

(3) Low Building Internal & External Wall

3 floor villa

Gym

Prefab house

Simple House

Staff domitory

Villa

Economic house

Resort

6. Packing details

Panels without packing

Well packed panels stacking area

Corner protected with cardboard

Shipping lable on each pallet

7. Loading details

Empty Container

Partial loading of the container

Forklift to transfer the panels into container

Fully loading of the container

8. Installation guide

1.Seeting the line

2. Sawing board

3. Apply cement adhesive

4. Installation: Carrying the board to installation place, correcting the board by gavelock &making it close tightly and let the cement adhesive squeeze out into full and fixing it with a chock temporarily.

5. Correcting: Using a guiding rule of two meters to check verticality and leveling correcting

Fixing: Using 6mm diameter reinforced steel bar & construction sealant to fix

6.Grouting &filling starch:

Filling and strickling the corrected wall board with cement adhesive, filling the big gap with fine stone concrete.

7. Sticking anti-crack tape & fiberglass mesh: Stick anti-crack tape on gap of panels, then stick fiberglass mesh on whole wall, thus to prevent the wall from crack

8. Installation electrical wires, switches & waterpipes

9. Painting (sticking ceramic tile or wall papers )

10. Installation door etc

11. Soft decoration etc

12. Electrical appliance installation

Remarks: 1-6 is about wall panel installation .7-12 is about follow-up construction & decoration projects.

Danas is solely responsible for 1-6 installation content.

9. Installation tools

Hammer

Electrical Hammer

Measuring Tape

Level Instrument

Electrical Cutter

Hand-held Electric Mixer

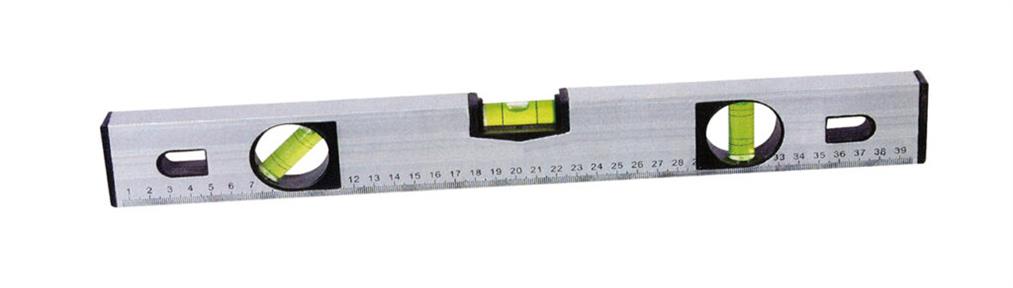

Level Ruler

Trowel

Remarks: If you like, we can help to puchase the installation tools & loading together with the wall panels in the container .

10. Installation accessories

Cement Adhesive

Usage: use to join the panels, used between the tongue and groove channels

Steel bar

Can be strip line and bended

Usage: link the two panels, make the wall more strength

Anti-crack Mortar

Usage: together with the fiberglass mesh, stick onto the whole wall, thus to prevent the wall from crack

Anti-crack tape

Usage: stick onto the gaps between the two panels, thus to prevent wall from crack

Fiberglass mesh

Usage: Together with the anti-crack cement mortar, stick onto the whole wall, thus to prevent wall from crack

Skim coat

Usage: For filling and leveling up, to make the wall surface smoothly & flat

Remarks: All the installation accessories, buy from us or buy from local do depend on your option.

If buy from us, we will calculate according to your wall panels quantity & loading together in the container.

11. About quality controll

More than 5 steps quality controll procedure before loading the panels:

1. Raw materials:

Raw material manufacturers make the quality checking first, then to delivery the goods together with qualification certificates. Upon raw materials arriving to our warehouse, warehouse keeper make a spot check of the goods, confirm up-to-standard,then receipt of goods.

2.During production:

With the automatic production line, strictly follow the raw material ratio, all of our raw materials are precisely weighed & convey to the mixing machines.

3. After finish production:

Upon wall panels taking out from the mould car, the QC check the goods quality firstly, up-to -standard goods transfer to the stacking area for maintenance. Inferior products transfer to another area for repairing.

4. Before Packing:

After well maintenance of the panels & before packing, QC check again the quality etc, upon qualified products then for packing.After packing, then waiting for loading &shipping etc.

5. Packing Details:

All panels fasten by the packing belt & wrapped with plastic thin film,edge protected by cardboard, thus can protect the panels during loading & unloading of the container.

12. After sales service

1. Unloading of goods:

We send you the unloading video of wall panels before arriving of the container, thus to guide you how to unloading the goods.

2. Checking quality:

After unloading the goods, please take out the outside packaging & check the goods quality soon as possible (suggest within 10 days after you receive the goods)

3. Happen to wall panel broken or corner breakage:

If you do found several pcs broken, or some pcs corner breakage, please do not worry about it.

- If this is only several pcs, less than 5% , it is because of the fluctuation during transportation.

Please kindly take some pictures & calculate the quantity, then we will send you extra pcs free during next time shipping of goods.

At same time, the broken area you can cut it and the well part you can use for installation

The breakage corner, can filling it by mortar or cut it, then to use for installation,thus to avoid wastage.

- If happen to more than 5% panels broken or corners breakage, suggest first calculate the quantity & send us pictures, we will investigate & feedback you within 24 hours. Please do not worry about it, always we responsible for our quality, will further discuss, analysis & offer you a satisfy solution.

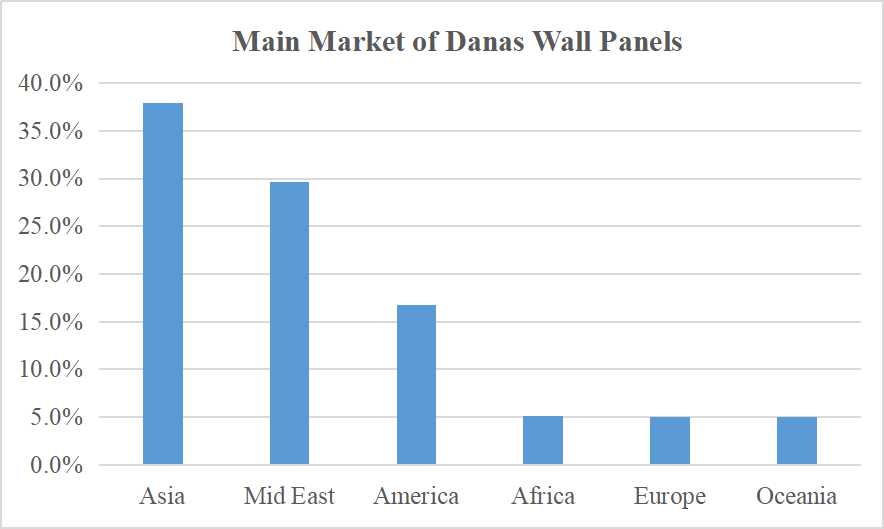

13. Our market

Asia: Philippines, Malaysia, Indonesia, Thailand, Vietnam, Brunei, Myanmar, Maldives, Sri Lanka, Pakistan etc

Mid East: Saudi Arabia, UAE, Iraq, Qatar, Baharain etc

America: USA, Uruguay, Chile, Bolivia, Columbia, Panama, Cost Rica etc

Africa: South Africa, Kenya, Egypt, Uganda, Morocco, Nigeria etc

Europe: Spain, Portugal, Sweden etc

Oceania: Australia, French Polynesia, Papua New Guinea etc

14. About us

ISO9001, ISO14001

10+ years manufacturer

Annual productivity 1,000,000m2

30000m2 land area

300+ valued clients

Wall panels without packing

Well packed panels

Panels loading into the container

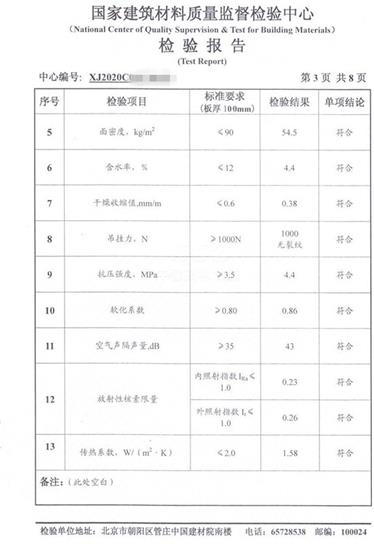

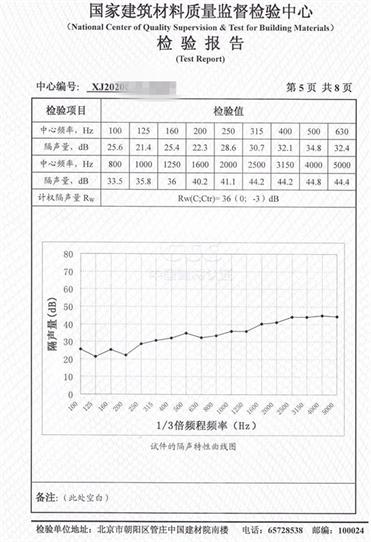

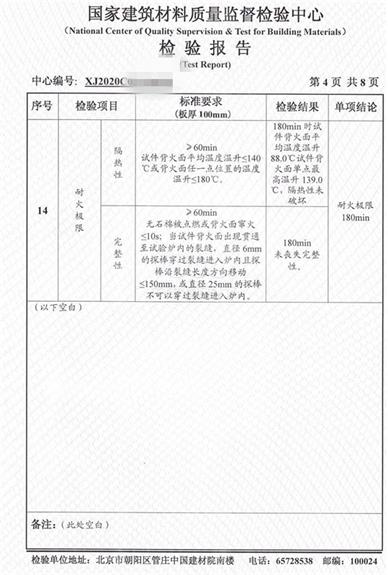

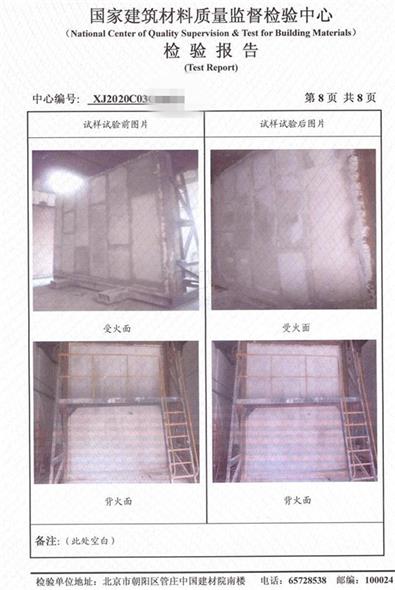

15. Testing report

Wall panel testing report

Sound insulation

Fire-resistance -1

Fire-resistance -2

Saber

Product certificate from QIMA

Remarks: Mainly use for Saudi Arabia market

Remarks: More testing report etc, suggest further discuss by email.

16. Cooperation procedure with Danas

(1) Send us enquiry

Email: sales@danasbuildingmaterial.com

Mobile/Whatsapp: +86-13317179258

Wechat: Danaswall

(2) Samples

You do intersted our wall panels & want a sample to check the quality

Can send by DHL, Fedex, UPS etc

(3)Price negotiation

Danas wall panel quotation —-your target price —bargain —bargain —finally agree by two sides

(4) Other terms discussing

Such as payment terms, delivery time, quality assurance, shipping plan etc

(5) Place order & deposit payment

All details confirmed, place an order, then we send you Proforma Invoice, you pay 30% deposit payment

(6)Production

Upon receive 30% deposit, will arrange production & will update the production process regularly

(7) Goods finished production

When goods finished production, we will show you the picture (video), you can arrange your QC to check the quality, then to arrange the balance payment

(8) Booking for container

Contact with the forwarder, booking container for loading the wall panels

(9) Loading goods

Loading the wall panels into container, take photos or videos thus to send client for reference

(10) Shipping documents

Send draft B/L, Packing list, Commercial invoice, CO etc for confirmation, then to send original sets or telex documents

(11) Tracking for container

Always track the container sailing details & remind client 7 days before container arrive to destination port , thus client can make customs clearance & pick up for containers etc in advance

(12) Unloading & quality checking

After pick up the container, unloading the goods, suggest check the quality within 10 days If happen to any broken pcs, please do not worry, we always here for your after service service

Remarks: This is the normal procedure, only for your basic reference. No need to follow all this step one by one, different client with different practice , welcome to contact for further details .

17. Danas other produts

Sandwich wall panel production line

Sandwich wall panel installation tools

Wall panel installation accessories

18. Contact with Danas

More details needed, feel free to contact with us

Website: www.danasbuildingmaterial.com Email: sales@danasbuildingmaterial.com

Mobile/Whatsapp: +86-13317179258 Wechat: Danaswall

Thank you so much for your kindly patience of our eps cement sandwich wall panel page, hope to cooperate with you in future.